Image 1 of 3

Image 1 of 3

Image 2 of 3

Image 2 of 3

Image 3 of 3

Image 3 of 3

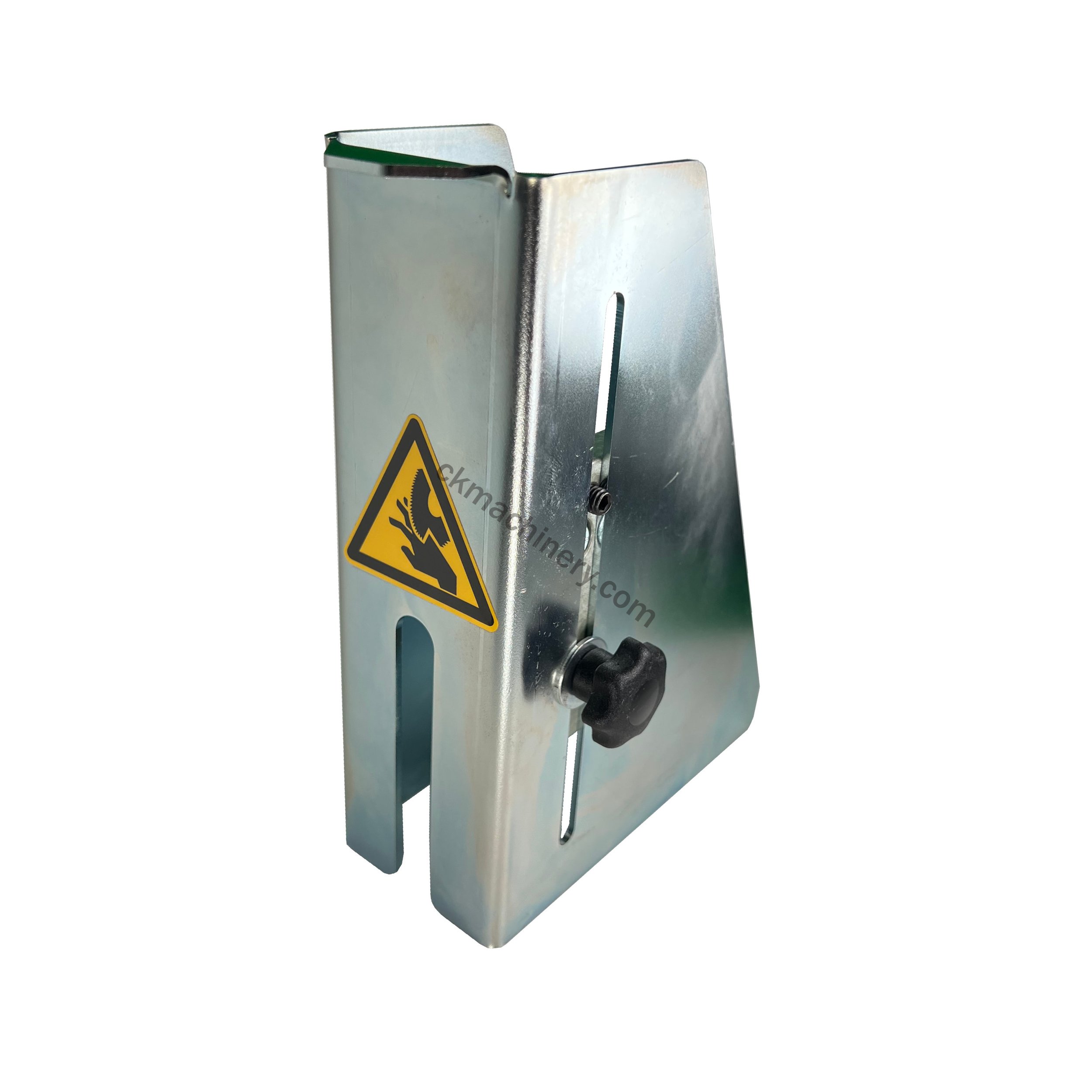

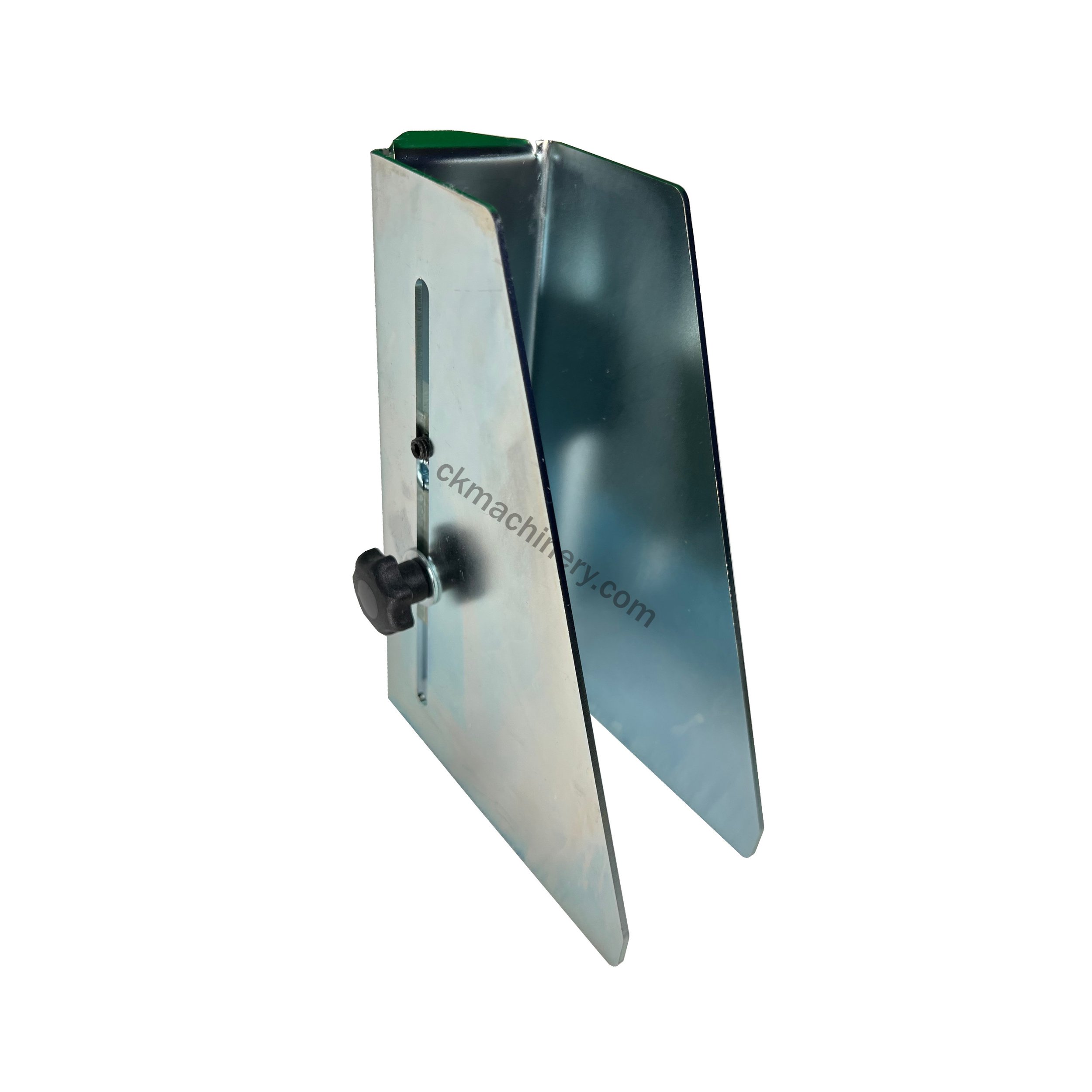

Graule ZS200 / ZS200N Linear Bearings (Set of 4)

Graule ZS200 / ZS200N Linear Bearings (Set of 4)

Genuine Graule Product from Germany

Set of 4 Bearings for a Graule ZS200 Cross Cut Saw

Replaces Bearings in the backwards / forwards cutting operation of the saw, over time they can become worn and need replacing to ensure free and easy movement

When fitting ensure the locating pin is properly aligned with the bearing

Ref: 04180202 / 09.03

Cutting and mitre circular saws type ZS200 /N

(8-row ball bushing)

With these machines, the Kpl. Saw carriages can be removed from the guide to the front.

•Disconnect the machine from the electrical network and remove the saw blade Hang the retraction tedre (old system) or the steel cable of the rope re circulation on the carriage.

•Install the front end strip at the end of the shaft If the machine has a hydraulic feed brake, remove it as well

•Loosen the side grub screw (top or bottom) slightly on the ball socket holder so that the preload of the ball bushing is releasedCAREFULly pull the complete saw head forward from the guide shafts. Be careful not to warp the guide elements. It may be helpful if this work is carried out by 2 men. Here one man holds the weight and the other man pays attention to a straight guide when playing.Alternatively, the saw head can only be pulled forwards or backwards from the guide so far that only 2 ball bushings are released and the carriage with the other twoBall rifles are still held on the guide.Remove ball rifles from holders. To do this, turn the grease nipple back.Insert a new ball bushing and fix it with grease nipples. Pay attention to the correct installation position of the ball bushing (fixing hole). Leave the cardboard sleeve in the ball bushing!

•Gently slide onto guide shafts, pushing out the cardboard sleeve.ATTENTION: Do not warp under any circumstances, because then the ball rifles burst!!.

•Screw in the side grub screw until you feel that the ball bushing is being tensioned .As soon as the grub screw comes into pressure, only tighten slightly.ATTENTION: No large preload must be applied to the ball bushing.

ALL PRICES + VAT and Delivery UK Shipping only

Graule ZS200 / ZS200N Linear Bearings (Set of 4)

Genuine Graule Product from Germany

Set of 4 Bearings for a Graule ZS200 Cross Cut Saw

Replaces Bearings in the backwards / forwards cutting operation of the saw, over time they can become worn and need replacing to ensure free and easy movement

When fitting ensure the locating pin is properly aligned with the bearing

Ref: 04180202 / 09.03

Cutting and mitre circular saws type ZS200 /N

(8-row ball bushing)

With these machines, the Kpl. Saw carriages can be removed from the guide to the front.

•Disconnect the machine from the electrical network and remove the saw blade Hang the retraction tedre (old system) or the steel cable of the rope re circulation on the carriage.

•Install the front end strip at the end of the shaft If the machine has a hydraulic feed brake, remove it as well

•Loosen the side grub screw (top or bottom) slightly on the ball socket holder so that the preload of the ball bushing is releasedCAREFULly pull the complete saw head forward from the guide shafts. Be careful not to warp the guide elements. It may be helpful if this work is carried out by 2 men. Here one man holds the weight and the other man pays attention to a straight guide when playing.Alternatively, the saw head can only be pulled forwards or backwards from the guide so far that only 2 ball bushings are released and the carriage with the other twoBall rifles are still held on the guide.Remove ball rifles from holders. To do this, turn the grease nipple back.Insert a new ball bushing and fix it with grease nipples. Pay attention to the correct installation position of the ball bushing (fixing hole). Leave the cardboard sleeve in the ball bushing!

•Gently slide onto guide shafts, pushing out the cardboard sleeve.ATTENTION: Do not warp under any circumstances, because then the ball rifles burst!!.

•Screw in the side grub screw until you feel that the ball bushing is being tensioned .As soon as the grub screw comes into pressure, only tighten slightly.ATTENTION: No large preload must be applied to the ball bushing.

ALL PRICES + VAT and Delivery UK Shipping only